Il divertimento delle persone poggia oggi su solide basi. Specialmente nel mondo online, i modi per intrattenersi sono ormai decine, grazie soprattutto a piattaforme ben studiate. Lo sport è, probabilmente, l’attività più funzionale in questo senso, grazie a varietà e tantissime opzioni di gioco. I bookmaker non AAMS sono solo l’ultima delle trasposizioni di questo universo, delle piattaforme straniere uniche che possono offrire grandi soddisfazioni.

Oggi scopriamo come muoversi adeguatamente in questo grande settore.

Migliori bookmaker non AAMS in Itaia del 2026

- Admiralbet: la soluzione trasparente per tutti. Bonus iscrizione SPID 1000€ + 500 FS

- Bwin: lo sport vissuto al 100%. Bonus nuovi arrivati fino a 550€

- Betsson: chiaro e dinamico nella proposta. Bonus di benvenuto 200€ senza deposito

- Gioco Digitale: il bookmaker a scorrimento più veloce. Bonus di benvenuto 2000€

- Planetwin: il posto giusto per una scommessa vincente. Bonus benvenuto a 2050€

- Snai: il nome perfetto da associare allo sport. Bonus di benvenuto fino a 1500€

- Sisal: la scelta completa con sport particolari. Bonus di ingresso fino a 6000€

- Sportbet: il gioco sportivo che ci piace. Bonus di benvenuto 200€ + 25% cashback

- William Hill: l’eleganza del portale più famoso. Bonus sportivo fino 205€

- VinciTu: il bookmaker veloce che guarda al passato. Bonus senza deposito a 2000€

I migliori bookmaker non AAMS: le nostre recensioni

Ad oggi, dunque, quali sono i migliori bookmaker non AAMS? La nostra squadra di professionisti del settore si è posta questa domanda, cercando una risposta direttamente sul campo. A seguire troverete dunque 10 recensioni tecniche. Queste sono state realizzate a seguito di un test diretto, che ha coinvolto e selezionato solo i portali migliori di questo settore.

Ne scoprirete punti forti e deboli, le migliori modalità di gioco, le opzioni di scommessa e le eventuali opportunità casinò. Iniziamo subito con la nostra serie di recensioni.

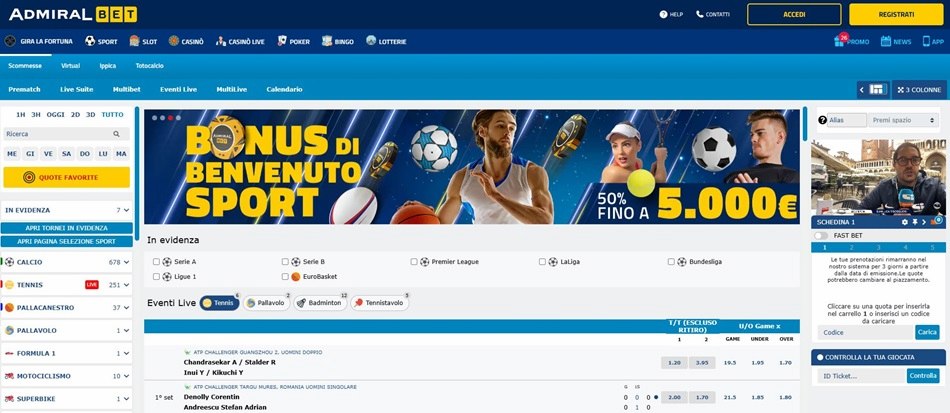

Admiralbet

Il primo sito di gioco di cui dobbiamo assolutamente parlare è Admiralbet. Questo particolare portale di gioco con licenza italiana si posiziona sul mercato come un bookmaker completo ed affidabile, il quale non manca di dimostrarlo. Gli sviluppatori di questo sito sanno bene infatti come le persone tendano più a diffidare, giustamente. Per questo motivo, il sito viene costruito per essere trasparente con i propri utenti, mostrando informazioni sulle proprie dinamiche di sicurezza.

Per dirne una: Admiralbet mostra subito il proprio codice di licenza, rendendo possibile la verifica da parte degli utenti. Questo richiama un indice di trasparenza molto alto, che dimostra la buona volontà della piattaforma.

Dal punto di vista dell’offerta, perciò, abbiamo un bookmaker di alto livello. Aprendo le porte della sezione scommesse, i giocatori avranno accesso a un mondo di sfide. La parte in alto della scheda è dedicata agli eventi del momento, filtrabili per disciplina o campionato. Scorrendo si possono quindi visualizzare diversi box: eventi live, last minute, top match e così via.

Sempre da questa schermata potrete inoltre visionare opportunità secondarie, come le multibet, gli eventi multilive e il calendario.

Tra le funzioni avanzate spicca sicuramente la fastbet. Questa permette di inserire una scommessa rapida con parametri scelti in un primo momento. Offre dunque la possibilità di semplificare il processo di puntata, snellendo e riducendo i tempi.

| Bookmaker online | AdmiralBet |

| Licenza attuale | Licenza ADM (precedentemente AAMS) |

| Sport più quotati | Calcio, tennis, pallacanestro, formula 1, automobilismo |

| Sezione casinò gaming | Disponibili |

| Metodi di pagamento accettati | Bonifico bancario, PayPal, Skrill e wallet, Carte, Postepay, MyPaysafeCard |

| Opzioni mobile | Accesso browser con sito responsive o download APK |

| Bonus di benvenuto | Bonus iscrizione SPID 1000€ + 500 FS |

Vantaggi:

- Chiaro con gli utenti.

- Quote maggiorate e tantissimi sport disponibili.

- Fastbet che semplifica i processi di puntata.

Svantaggi:

- Alcune partite non godono di grandi quote.

Bwin

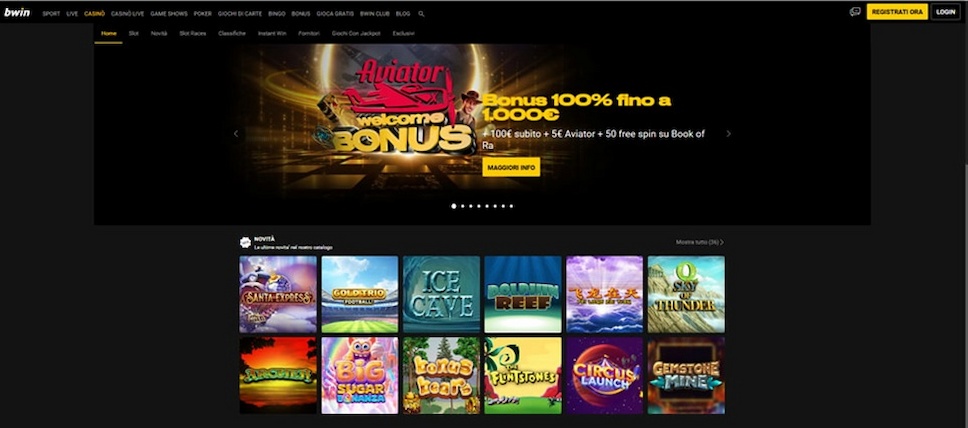

Un altro portale su cui sarebbe saggio puntare gli occhi, specie nel mondo dello sport, è Bwin. Questo è uno di quei siti di gioco grandi e famosi, con una grande reputazione alle spalle ed un mondo di opportunità. Si lancia sul mercato come un sito di gioco generico. In realtà però, Bwin è principalmente noto per essere un bookmaker di alto livello. Questo lo dimostra la sezione dedicata, che è anche la prima che appare accedendo al sito.

Aprendo Bwin, infatti, l’homepage viene sostituita direttamente con la pagina “sport”, che rappresenta anche il centro dell’offerta. L’utente viene dunque subito catapultato all’interno del bookmaker, potendo visionare così sin da subito le migliori opportunità del momento.

Il portale comincia infatti mostrando subito i match della giornata, gli orari e le quote per i mercati essenziali. Scorrendo, si possono approfondire gli stessi eventi, così come visualizzare i match in partenza, quelli live, le top prematch e le scommesse più giocate. Sempre nella stessa pagina, il giocatore avrà a disposizione diversi box (uno per ogni sport), dove gli eventi saranno filtrabili per campionato.

Dal punto di vista organizzativo, Bwin è semplice ma efficace. Sulla sinistra raccoglie il meglio dello sport che ha da offrire, mentre sulla destra potrete trovare le vostre scommesse piazzate.

| Bookmaker online | Bwin |

| Licenza attuale | Licenza ADM (precedentemente AAMS) |

| Sport più quotati | Calcio, basket, tennis, rugby union, pallavolo, hockey, sport a motori |

| Sezione casinò gaming | Disponibili |

| Metodi di pagamento accettati | Carte, Postepay |

| Opzioni mobile | Accesso browser con sito responsive o download APK |

| Bonus di benvenuto | Bonus nuovi arrivati fino a 550€ |

Vantaggi:

- Offerta sportiva molto grande.

- Buone soluzioni di gioco anche per il casinò.

- Comprende tornei race anche per il poker.

Svantaggi:

- Non esiste una vera “homepage”.

Betsson

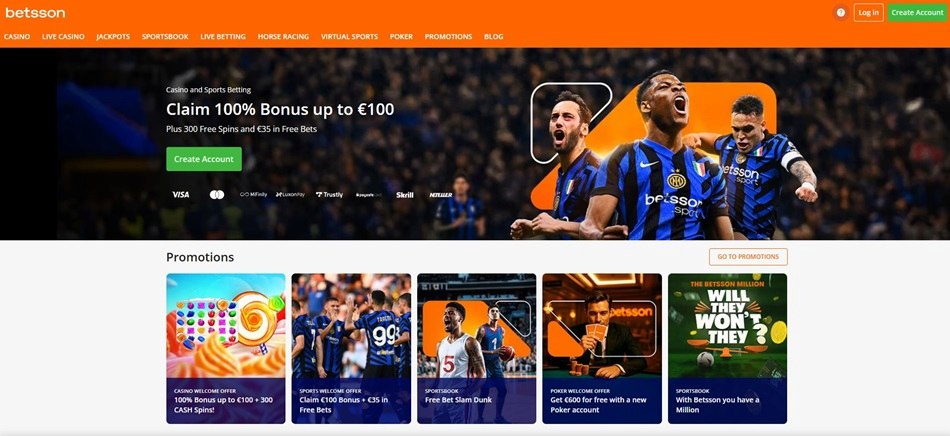

Proseguendo nella nostra scoperta dei migliori bookmaker online, un altro sito a cui gli utenti dovrebbero dare una chanche è Betsson. Questo portale di gioco può indubbiamente essere un’ottima soluzione per moltissime tipologie di giocatore. Al contrario di molti portali di questo tipo, infatti, Betsson punta a snellire le procedure, per offrire un’esperienza veloce e dinamica. Nel farlo ha costruito quindi un sito molto intuitivo, con pochi pulsanti e relativi menù a tendina.

Betsson arriva sugli schermi dei giocatori come un casinò online. Ben presto, però, la sua predisposizione sportiva ha preso il sopravvento, controllando ora diversi elementi ludici.

La sua sezione sportiva è accessibile dal relativo pulsante, che consente anche di accedere a singole sezioni separate. Gli utenti possono dunque visualizzare singolarmente anche prematch, ippica e virtuali. “Sport prematch” è la sezione generale, che comprende appunto tutte le possibilità di puntata prematch. Dal calcio al tennis, passando per golf, sport a motori e badminton. Potrete visualizzare quote, statistiche di mercato e campionati per ogni singola disciplina.

Se siete più tipi da improvvisazione, la sezione “sport live” vi offrirà la possibilità di scommettere su match in corso.

Molto interessante poi il compartimento dedicato alle scommesse sull’ippica. Questo mostra dettagli su corse, cavalli singoli e fantini, piste e meteo, proponendo quindi diverse chiavi di lettura per i singoli pronostici.

| Bookmaker online | Betsson |

| Licenza attuale | Licenza ADM (precedentemente AAMS) |

| Sport più quotati | Ippica, calcio, tennis, basket, pallavolo, badminton |

| Sezione casinò gaming | Disponibili |

| Metodi di pagamento accettati | Bonifico bancario, PayPal, Skrill e wallet, Carte, PaysafeCard, OnShop, ApplePay e Google |

| Opzioni mobile | Accesso browser con sito responsive o download APK |

| Bonus di benvenuto | Bonus di benvenuto 200€ senza deposito |

Vantaggi:

- Sezione ippica di alto livello.

- Propone quote interessanti anche su mercati poco frequentati.

- Le promozioni sono spesso orientate allo sport.

Svantaggi:

- Potrebbe essere modernizzato graficamente.

Gioco Digitale

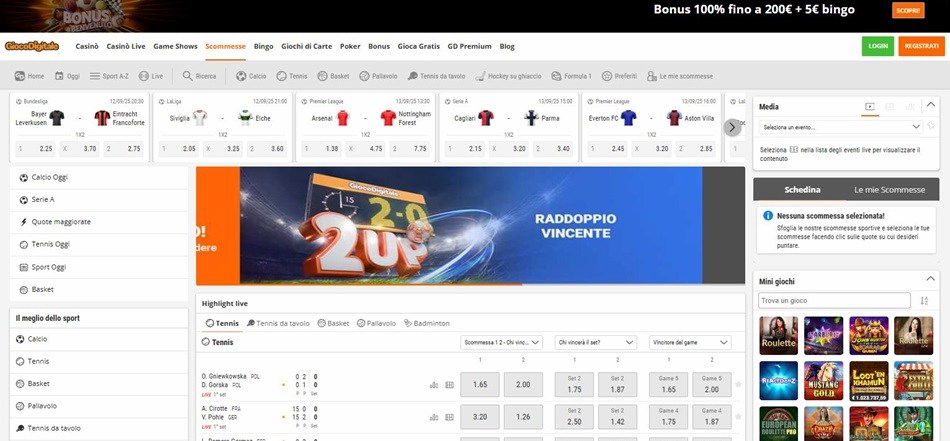

Gioco Digitale è uno di quei bookmaker e siti di gioco online che più di altri hanno definito lo standard da seguire. In questo specifico caso parliamo infatti di un sito di gioco che ha fatto della rapidità il suo principale marchio di fabbrica. Per incentivare anche gli utenti meno esperti ad iscriversi, infatti, ha costruito un portale veloce da navigare, senza sottomenù secondari. In questa maniera, tutto è a portata d’occhio sin dal primo momento, facilitando i primi passi.

Ogni singola sezione di gioco è quindi navigabile direttamente dalla barra superiore. I pulsanti sono veloci e restituiscono le pagine di destinazione in pochissimo tempo. Cliccando su “scommesse”, perciò, avrete accesso al bookmaker sportivo.

Qui ritroviamo la forma classica e funzionale che abbiamo già visto con altri grandi nomi. Inizialmente vengono proposte le quote migliori della giornata, con vari box e finestre che mirano ad approfondire diverse discipline. Il palinsesto qui è particolarmente ricco, con opportunità per calcio, basket e tennis, ma anche sport come il golf.

A rendere tutto più vario ci pensano poi sport diversi dal solito, come gli scacchi e lo sci alpino.

Gioco Digitale è però anche rinomato per la propria componente casinò, che permette di avvicinarsi a titoli come slot e poker.

| Bookmaker online | Gioco Digitale |

| Licenza attuale | Licenza ADM (precedentemente AAMS) |

| Sport più quotati | Calcio, tennis, basket, golf, sci alpino, scacchi, eventi di spettacolo e politica |

| Sezione casinò gaming | Disponibili |

| Metodi di pagamento accettati | Bonifico bancario, PayPal, Skrill e wallet, Carte, ApplePay e Google |

| Opzioni mobile | Accesso browser con sito responsive o download APK |

| Bonus di benvenuto | Bonus di benvenuto 2000€ |

Vantaggi:

- Costruzione del sito semplificata per tutti.

- Sezione sport con discipline diverse dal solito.

- Comprende anche tantissime slot machine e game show.

Svantaggi:

- Non accetta Paysafecard.

Planetwin

Se quello che cercate dovesse invece essere principalmente qualcosa di legato esclusivamente allo sport, Planetwin potrebbe interessarvi. In questo caso, infatti, ci riferiamo ad un bookmaker che fa dello sport la propria vocazione principale, anche se non manca di spaziare. Entrando in questo sito, dunque, verrete condotti ad una homepage generale, che punta a mostrare tutte le potenzialità del sito.

Già dai primi passi, l’utente viene messo a contatto con la sezione sportiva del sito, che mostra le migliori quote del momento. Queste possono essere approfondite cliccando su “scommesse”, e visionando la sezione bookmaking. Nonostante Planetwin non sia uno dei più conosciuti, il suo bookmaker compete alla grande con altri siti più grandi e blasonati.

Anche qui ritroviamo la classica struttura a scorrimento, che mette in elenco tutte le partite più interessanti dello sport selezionato. La zona centrale è dedicata quindi a top live, prossimi eventi e migliori possibilità prematch. Le partite visualizzate possono quindi essere filtrate per queste tre categorie, oppure per sport, cliccando sugli appositi pulsanti.

La particolarità che rende questo bookmaker interessante è che, tutte le quote e su tutti i mercati, vengono aggiornate in tempo reale. Le quote quindi cambiano da un momento all’altro, mostrando le fluttuazioni di mercato, nuove variabili o tendenze degli altri utenti. Questo può essere un elemento fondamentale nella scelta dei propri pronostici.

Planetwin comprende infine anche casinò, slot e giochi live, con tavoli poker e bingo.

| Bookmaker online | Planetwin |

| Licenza attuale | Licenza ADM (precedentemente AAMS) |

| Sport più quotati | Calcio, tennis, basket, padel, volley, hockey, baseball, badminton |

| Sezione casinò gaming | Disponibili |

| Metodi di pagamento accettati | PayPal, Skrill e wallet, Carte, Postepay |

| Opzioni mobile | Accesso browser con sito responsive o download APK |

| Bonus di benvenuto | Bonus benvenuto a 2050€ |

Vantaggi:

- Quote che si aggiornano in tempo reale.

- Risposte del server incredibilmente veloci.

- Comprende bonus per ogni sezione di gioco.

Svantaggi:

- Ancora poco noto nel settore.

Snai

Qualsiasi genere di giocatore, anche solo un minimo appassionato allo sport, conosce sicuramente la piattaforma Snai. Questo è uno dei siti di gioco online più famosi e importanti del settore, il quale è oggi la scelta principale degli utenti. La sua selezione sportiva è infatti una delle più grandi e raffinate nel settore, mentre la sua precisione nelle quote proposte non ha eguali. Tutti questi elementi si incastrano con un’ottimizzazione intelligente della piattaforma, che raccoglie e schematizza tutto rendendolo accessibile.

Anche qui troviamo una homepage piuttosto generica, che mostra al giocatore le potenzialità della piattaforma. Snai non è infatti solo un bookmaker, ma un vero e proprio casinò online, con tanto di sezioni per slot, poker e blackjack. La componente sportiva è però preponderante, attirando la maggior parte del traffico.

Ecco dunque che cliccando su “scommesse” si può accedere alle diverse sottosezioni del catalogo relativo. Ci sono “sport”, “virtual”, “live” e “ippica”, tutte approfondibili con sezioni uniche a parte. La prima pagina è quella generale che raccoglie un po’ tutte le potenzialità di gioco.

Vengono mostrati subito gli sport accessibili, mentre nella parte sottostante sono elencati i match più interessanti del momento. Le opportunità sono filtrabili per disciplina e manifestazione, offrendo così una personalizzazione più mirata.

| Bookmaker online | Snai |

| Licenza attuale | Licenza ADM (precedentemente AAMS) |

| Sport più quotati | Calcio, ippica, tennis, basket, volley, sci alpino, football americano |

| Sezione casinò gaming | Disponibili |

| Metodi di pagamento accettati | PayPal, Skrill e wallet, Carte, Postepay, SnaiPay, Bonifico |

| Opzioni mobile | Accesso browser con sito responsive, download APK o Apple Store |

| Bonus di benvenuto | Bonus di benvenuto fino a 1500€ |

Vantaggi:

- Il più grande bookmaker del momento.

- Comprende tantissimi sport anche di nicchia.

- Sezione casinò molto ricca e completa.

Svantaggi:

- Sezioni bingo un po’ scarne.

Sisal

Con Sisal non parliamo di un semplice bookmaker online, né di un casinò banale come altri. Sisal è infatti un vero pool di gioco totalizzante e completo, il quale domina incontrastato tra le scelte per le ricevitorie fisiche. Qualora decideste di posizionare una giocata in una tabaccheria, ad esempio, il circuito Sisal sarà quello selezionato dall’operatore. Questa non è però una scelta solo “di moda”, in quanto questo portale merita pienamente la fiducia che gli viene riposta.

All’interno delle sue pagine racchiude infatti le migliori opzioni per decine di categorie. Si spazia dunque dal casinò alle lotterie, passando per bingo, poker e arrivando ovviamente anche alle scommesse. Qui, il bookmaker è incredibilmente soddisfacente, proponendo una visione completa che include ippica, live, virtual e totocalcio.

Accedendo al bookmaker vedrete tutte le migliori proposte del sito. Dalle migliori combo ai migliori eventi live, nonché quelli in partenza e quelli programmati. Le quote sono chiare e leggibili immediatamente, con panoramiche e dettagli su mercati e statistiche di vario tipo.

Scorrendo, dopo la sezione dei suggerimenti. è presente anche il classico elenco a scorrimento. Questo è costruito con filtri di ricerca e quote aggiornate in tempo reale. Molto interessante, sempre in questa sezione, è l’integrazione di Tipster, il social network delle scommesse sportive.

| Bookmaker online | Sisal |

| Licenza attuale | Licenza ADM (precedentemente AAMS) |

| Sport più quotati | Calcio, tennis, basket, sci alpino, volley, automobilismo, ciclismo, Esports |

| Sezione casinò gaming | Disponibili |

| Metodi di pagamento accettati | PayPal, Skrill e wallet, Carte, Postepay, Bonifico, Paysafecard |

| Opzioni mobile | Accesso browser con sito responsive, download APK o Apple Store |

| Bonus di benvenuto | Bonus di ingresso fino a 6000€ |

Vantaggi:

- Ottima scelta per le giocate dal vivo.

- Presenza di Tipster nella sezione scommesse.

- Tante lotterie disponibili.

Svantaggi:

- La sua grande varietà rischia di confondere i neofiti.

Sportbet

Tornando nella nicchia dei siti pensati esclusivamente per il pubblico interessato allo sport, Sportbet è un nome nuovo ma interessante. Come suggerisce il nome, infatti, questo portale di gioco è stato progettato proprio per le scommesse ed il betting. Nel farlo, comunque, comprende anche delle piccole sezioni dedicate a casinò e giochi come slot e poker. Questo gli consente di essere vario e preciso al tempo stesso, con tante opzioni per altrettante categorie di utente.

Sportbet è però un asso nello sport, ovviamente. Accedendo alla pagina bookmaking, dunque, avrete immediatamente una visione chiara delle opportunità. Il sito non perde tempo, e propone subito dei suggerimenti di scommessa su eventi selezionati. A volte possono anche includere delle quote maggiorate.

Scorrendo, comunque, potrete scoprire quali sono gli eventi più interessanti in partenza, suddivisi per tipologia di scommessa. Ci sono quindi eventi prematch, ma anche live, last minute e calendarizzate. Ogni tipologia di scommessa ha le proprie discipline principali, con quote selezionate su tantissimi mercati per ogni match. Il live betting è comunque una parte molto più importante di quanto sembri. Per questo, la piattaforma gli ha dedicato una pagina a sé, accessibile tramite pulsante.

Sportbet però cerca anche di offrire qualcosa in più. Lo fa ad esempio inserendo la fastbet, la scommessa rapida che abbiamo già visto in altri siti dello stesso genere.

| Bookmaker online | Sportbet |

| Licenza attuale | Licenza ADM (precedentemente AAMS) |

| Sport più quotati | Calcio, badminton, freccette, tennis, pallacanestro, cricket |

| Sezione casinò gaming | Disponibili |

| Metodi di pagamento accettati | PayPal, Skrill e wallet, Carte, Postepay, Bonifico |

| Opzioni mobile | Accesso browser con sito responsive, download APK o Apple Store |

| Bonus di benvenuto | Bonus di benvenuto fino a 200€ con il 25% di cashback |

Vantaggi:

- Presenza di fastbet.

- Proposte del sito con quote maggiorate.

- Sezione ippica molto dettagliata.

Svantaggi:

- Alcune opportunità casinò sono un po’ deboli.

William Hill

Chi ha già esplorato autonomamente il mondo dei siti di gioco online, sicuramente avrà già sentito nominare William Hill. Questo è infatti uno dei siti più famosi nel settore del gioco online, proprio perché uno dei primi a lanciarsi con un’offerta moderna. William Hill è stato infatti pioniere di tantissime cose, come ad esempio l’unione di diverse categorie ludiche sotto lo stesso tetto. Su questo sito potrete infatti giocare tanto al casinò quanto scommettere sullo sport, sfruttando le singole sezioni dedicate.

Il primo approccio con questo sito è decisamente generale. La homepage è infatti costruita bene, offrendo uno spaccato totale del portale. Le diverse sezioni di gioco sono visualizzabili cliccando semplicemente sui pulsanti dedicati. In alto troverete infatti l’accesso a scommesse, casinò, casinò live, poker e bingo.

La sezione dedicata alle scommesse è una delle più interessanti di questo sito di gioco. Riprende in parte la struttura classica che abbiamo visto con altri siti, inserendo però delle dinamiche che rendono tutto un attimo più dinamico. Sono presenti ad esempio delle piccole finestre a scorrimento per le proposte del sito. Sopra sono invece inseriti pulsanti che permettono di accedere all’event builder, oppure alle multiple combo.

La parte inferiore comprende invece la visualizzazione classica, con eventi di spicco per sport diversi.

Questa attenta organizzazione è disponibile anche per le altre sezioni di gioco, che rendono William Hill perfetto anche per il casinò.

| Bookmaker online | William Hill |

| Licenza attuale | Licenza ADM (precedentemente AAMS) |

| Sport più quotati | Calcio, tennis, basket, tennis tavolo, hockey, baseball, floorball |

| Sezione casinò gaming | Disponibili |

| Metodi di pagamento accettati | PayPal, Skrill e wallet, Carte, Postepay, Bonifico |

| Opzioni mobile | Accesso browser con sito responsive, download APK o Apple Store |

| Bonus di benvenuto | Bonus sportivo fino 205€ |

Vantaggi:

- Portale famoso e conosciuto.

- Sezioni casinò ben strutturate.

- Promozioni che si aggiornano nel tempo.

Svantaggi:

- Le proposte bonus potrebbero essere migliorate.

VinciTu

Per concludere, l’ultima piattaforma che vogliamo inserire in questa serie di recensioni è VinciTu. Se non conoscete questo sito di gioco, probabilmente è per via della sua “giovinezza”. Questo sito è infatti giunto da poco sul mercato, proponendosi come una novità classica e semplicissima per tutti. VinciTu viene infatti costruito come uno dei primissimi siti di gioco online, con barra di selezione e opzioni a scorrimento.

Dalla home si possono quindi scoprire i bonus del momento, insieme a tutti i giochi principali offerti dalla piattaforma. Ci sono quindi dettagli su casinò, poker e bingo, nonché sugli eventi sportivi più importanti e con le quote più interessanti. Per approfondire, comunque, basta cliccare sul pulsante “scommesse”, uno dei primi nella barra di selezione.

Il bookmaker che viene proposto è quindi semplice e molto intuitivo. Mostra diverse tipologie di evento, con filtri che coinvolgono sport, manifestazioni o persino mercati specifici. Sulla sinistra sono inseriti tutti gli sport su cui è possibile scommettere, mentre a destra è presente l’opzione di scommessa rapida.

Interessante qui è la sezione statistiche. Questa permette di visionare statistiche di gioco su eventi precisi, selezionando sport, paese e manifestazione. Questo permette di migliorare i propri ragionamenti ed i propri pronostici.

| Bookmaker online | VinciTu |

| Licenza attuale | Licenza ADM (precedentemente AAMS) |

| Sport più quotati | Basket, calcio, ippica, tennis, volley, padel, badminton, freccette |

| Sezione casinò gaming | Disponibili |

| Metodi di pagamento accettati | Carte |

| Opzioni mobile | Accesso browser con sito responsive, download APK |

| Bonus di benvenuto | Bonus senza deposito a 2000€ |

Vantaggi:

- Novità di alto livello nel mercato.

- Propone anche le lotterie ed il bingo.

- Contiene scommesse sulle freccette.

Svantaggi:

- Accetta solo carte di pagamento.

Bookmaker non AAMS: perché giocare all’estero

Nella dinamica moderna in cui ogni opportunità di gioco deve essere soppesata con attenzione, parlare di bookmaker non AAMS è importante. Per gli scommettitori, si tratta di un’opportunità da non mancare, anche se in molti potrebbero chiedersi perché giocare con portali stranieri. La risposta a questa domanda sta proprio nella licenza.

I bookmakers non AAMS sono siti che non possiedono la licenza ADM, ossia quella italiana. Questo avviene proprio perché sono portali esteri, e questo consente loro di sfruttare licenze operative straniere, diverse.

Il vantaggio risiede dunque nell’assenza dei tipici vincoli italiani che sono invece presenti con la licenza AAMS. I portali stranieri sono quindi più liberi di sperimentare, possono offrire quote più elevate, bonus maggiorati e persino giochi innovativi.

Scopriremo di più nel corso delle prossime righe.

Registrazione e autenticazione nei bookmaker non AAMS

La natura straniera e differente dei bookmaker non AAMS non va però a modificare molto il processo di iscrizione. Questa è infatti la fase essenziale del percorso, quella che immette l’utente all’interno del flusso di gioco. Anche se alcuni dettagli possono cambiare, i princìpi rimangono immutabili tra le diverse piattaforme.

- Si comincia attivando la registrazione, con il pulsante “registrati” o “iscriviti”.

- Tutti i bookmakers non AAMS procedono chiedendo username, password e email.

- Essendo portali stranieri, la verifica e l’autenticazione avvengono tramite link alla mail.

- Il giocatore può accedere al portale con le proprie credenziali.

- Viene chiesto di scegliere il bonus di benvenuto, e di effettuare il primo deposito.

Migliori Bookmakers non AAMS del 2026 a confronto

| Bookmaker | Depositi e prelievi sul sito | Bonus di benvenuto | Rating |

| Admiralbet | Bonifico bancario, PayPal, Skrill e wallet, Carte, Postepay, MyPaysafeCard | Bonus iscrizione SPID 1000€ + 500 FS | ⭐⭐⭐⭐⭐ |

| Bwin | Carte, Postepay | Bonus nuovi arrivati fino a 550€ | ⭐⭐⭐⭐☆ |

| Betsson | Bonifico bancario, PayPal, Skrill e wallet, Carte, PaysafeCard, OnShop, ApplePay e Google | Bonus di benvenuto 200€ senza deposito | ⭐⭐⭐⭐☆ |

| Gioco Digitale | Bonifico bancario, PayPal, Skrill e wallet, Carte, ApplePay e Google | Bonus di benvenuto 2000€ | ⭐⭐⭐⭐⭐ |

| Planetwin | PayPal, Skrill e wallet, Carte, Postepay | Bonus benvenuto a 2050€ | ⭐⭐⭐⭐☆ |

| Snai | PayPal, Skrill e wallet, Carte, Postepay, SnaiPay, Bonifico | Bonus di benvenuto fino a 1500€ | ⭐⭐⭐⭐⭐ |

| Sisal | PayPal, Skrill e wallet, Carte, Postepay, Bonifico, Paysafecard | Bonus di ingresso fino a 6000€ | ⭐⭐⭐⭐⭐ |

| Sportbet | PayPal, Skrill e wallet, Carte, Postepay, Bonifico | Bonus di benvenuto fino a 200€ e con il 25% di cashback | ⭐⭐⭐⭐☆ |

| William Hill | PayPal, Skrill e wallet, Carte, Postepay, Bonifico | Bonus sportivo fino 205€ | ⭐⭐⭐⭐⭐ |

| VinciTu | Carte | Bonus senza deposito a 2000€ | ⭐⭐⭐⭐☆ |

Come effettuare la valutazione dei bookmakers non AAMS

Pur partendo da definizioni e tematiche simili, molti siti non AAMS pensati per le scommesse propongono differenze in alcuni aspetti. Proprio per evitare di perdersi tra i vari portali e le varie dinamiche, è quindi importante sapere cosa guardare durante una valutazione concreta. Esistono infatti degli elementi, comuni appunto, che possono offrire uno spaccato informazionale decisamente utile.

Parliamo di dettagli che mutano tra un casinò online e l’altro, e che possono modificare direttamente l’esperienza generale. Abbiamo raccolto 4 di questi elementi principali, ognuno dei quali riveste un’importanza strategica per i siti scommesse non AAMS.

Cerchiamo di capire come eseguire questa valutazione.

Palinsesto sportivo dei bookmaker non AAMS

Parlando nello specifico di migliori bookmakers non AAMS, è fondamentale partire proprio dal palinsesto sportivo. Quando diciamo “palinsesto” ci riferiamo proprio alla selezione di discipline e sport su cui è possibile piazzare una scommessa. La licenza straniera consente infatti di ampliare il classico palinsesto, andando ben oltre le classicità italiane. In questo modo, si possono approcciare sport anche molto particolari, con un pubblico decisamente di nicchia.

Oltre alle novità, però, un buon palinsesto in un bookmaker non AAMS contiene ovviamente anche gli sport più classici. Non devono dunque mancare calcio, basket, tennis o pallavolo. In generale, vale la regola del “più c’è e meglio è”.

Anonimato nei bookmaker non AAMS

Spostandoci un attimo sul lato tecnico dei bookmaker non AAMS, un altro aspetto da non tralasciare riguarda ovviamente l’anonimato. Si tratta di un carattere importante, in questo caso, in quanto espletato alla perfezione proprio dai siti non AAMS in generale. Questi portali, non essendo in possesso di una licenza italiana, possono anche bypassare i controlli KYC.

Tali controlli, di norma, prevedono la verifica dell’identità attraverso i documenti personali di ogni giocatore. L’assenza di questi controlli, perciò, evita la dispersione di dati sensibili ed estremamente personali, legati ai documenti. In questo modo si può giocare nel totale anonimato, riducendo il rischio di furti di identità.

Sicurezza dei dati nei bookmakers non AAMS

Insieme all’anonimato, dunque, ricordate di controllare lo stato della sicurezza generale della piattaforma. Nei bookmakers non AAMS, la sicurezza è un elemento deputato ai protocolli SSL. Altrettanto importanti sono anche elementi come le meccaniche di crittografia avanzate ed i metodi di pagamento certificati.

I protocolli SSL, in particolare, devono sempre essere aggiornati, in quanto hanno un compito centrale. Permettono infatti di crittografare le “conversazioni” tra il server dell’utente e quello dei bookmaker non AAMS. In questa maniera si salvaguardano tutte le informazioni potenzialmente sensibili, che potrebbero finire nelle mani sbagliate. Accertatevi dunque che i protocolli di protezione seguano aggiornamenti cadenzati.

Bonus e promozioni dei siti non AAMS

Infine, per una valutazione che consideri l’interessa dei siti scommesse non AAMS, non tralasciate l’aspetto dei bonus. I bonus di gioco sono infatti delle opportunità offerte direttamente dai migliori siti scommesse non AAMS. Nuovamente, la loro licenza straniera permette di potenziare notevolmente le opportunità, offrendo dei bonus con cifre spesso molto elevate. Ciò non può accadere nei casinò online italiani, in quanto ADM limita e controlla questo aspetto.

Dovreste quindi optare per delle piattaforme con dei bonus interessanti, avendo a disposizione tantissime opportunità.

Le quote e il payout nei bookmakers non AAMS: come funzionano

Per essere coscienti davvero del valore dei pronostici nei bookmaker non AAMS sicuri, è importante conoscere il significato di quote e payout.

Le quote sono un valore nominale che viene assegnato alla probabilità di avvenimento di un preciso evento. Più alta è la quota, e meno sarà probabile (secondo il bookmaker) che l’evento accada. Alcuni bookmaker non ADM permettono di scegliere tra diversi formati di quota (decimale, frazionale o americana), offrendo maggiore flessibilità. Comprendere questa dinamica permette non solo di ponderare bene le proprie scelte, ma anche di confrontare le offerte di diversi siti di scommesse non AAMS.

Allo stesso tempo, è bene conoscere anche il concetto di payout. Questo indica la percentuale media restituita ai giocatori sotto forma di vincite. Un payout molto elevato, ad esempio sul 98%, evidenza come le quote proposte siano effettivamente molto vicine alle reali probabilità. Scegliere solo portali con questo genere di valori permette quindi di assicurarsi un certo livello di attenzione e tranquillità.

Questi due valori, associati, possono offrire dettagli nascosti sulla reale affidabilità dei bookmakers senza licenza. Tra l’altro, la natura straniera di queste piattaforme offre la possibilità di sfruttare incentivi migliori, svincolati dai limiti ADM.

Gli sport disponibili nei siti non AAMS sportivi

| Sport | Varietà di mercati | Analizzabilità (statistiche, dati, modelli) | Frequenza degli eventi |

| Calcio | Molto grande. Mercati come 1X2, goal, handicap, corner, marcatori | Enorme quantità di dati disponibili sia sulle piattaforme che online. | Quotidiana, anche più di un evento nello stesso giorno. |

| Basket | Grande e con varie opportunità. Mercati come punti totali, handicap, parziali | Presenti persino le statistiche individuali dei singoli giocatori. | Quotidiana. |

| Tennis | Grande con mercati disponibili su vincente set, game, over/under. | Disponibili le statistiche dei giocatori per ogni match/set. | Quotidiana ma solo ad aperta stagione. |

| Sport a motori | Ristretta ma comunque larga su eventi come podio, vincente, giro veloce | Livello medio, con informazioni piuttosto diffuse online. | Settimanale in aperta stagione. |

Calcio nei migliori bookmaker non AAMS

Il calcio è lo sport più famoso e richiesto nei bookmakers senza AAMS. Questa disciplina comprende infatti tantissimi mercati per i propri match, coinvolgendo anche opportunità rare. Si può infatti scommettere su classiche puntate 1X2 fino agli handicap asiatici, gol e combo. Rispetto ai siti italiani, i migliori bookmaker senza ADM possono allargare molto il palinsesto finale.

Basket nei migliori siti scommesse non AAMS

Quasi importante come il calcio, il basket è un’altra di quelle discipline evergreen immancabili nei migliori bookmaker non ADM. Comprende sempre eventi come Euroleague ed NBA, con mercati su punti totali, handicap e singole prestazioni dei giocatori. Uno sport dal ritmo di gioco molto veloce, perfetto per chi cerca più variabili da considerare contemporaneamente.

Tennis nei siti non AAMS

I bookmakers senza licenza AAMS comprendono sempre anche il tennis. Questo è uno sport molto particolare e sicuramente differente rispetto agli altri appena menzionati. Gode di grande spazio e copertura costante durante tutto l’anno, con mercati su game, set e vincente finale. Gli eventi sono moltissimi, comprendendo ovviamente gli ATP e i tornei Challenger.

Sport a motori

Anche se potrebbe non sembrare, gli sport a motori sono un’altra delle grandi opportunità del mondo dei siti non AAMS sicuri. Formula 1, MotoGP e rally trovano qui la loro massima espressione, offrendo eventi come corse internazionali e campionati speciali. Si può dunque scommettere su vincente gara, piazzamenti o tempi sul giro, a seconda dello sport specifico scelto.

Gli eSports e la loro rilevanza nei siti scommesse non AAMS

Come abbiamo anticipato, i migliori bookmakers non AAMS affidabili cercano di proporre quante più novità possibili. Tra queste uniche novità, gli eSports emergono forti e potenti, con un pubblico immenso e delle opportunità di altissimo livello. Ad oggi, si tratta di una delle frontiere più remunerative dei bookmaker non AAMS, e del betting online in generale.

Si tratta di puntate su campionati videoludici che fanno riferimento a precisi videogiochi.

Parliamo di grandi nomi, come League of Legends (su tutti), ma anche Counter-Strike 2, Dota 2 e Valorant. Queste competizioni offrono non solo uno sport in più su cui scommettere, ma un’opportunità per cimentarsi in un qualcosa costantemente in evoluzione.

Ogni partita è influenzata da strategie, reattività e coordinazione di squadra. Altri elementi possono essere cambiati da patch, mappe e bilanciamenti di gioco che mutano nel tempo. Per questo si può scommettere su una grande varietà di mercati, come quelli su uccisioni, mappe vinte o risultati esatti.

Le scommesse live sui siti scommesse non AAMS

Altra grande opportunità di gioco nei bookmakers non AAMS riguarda le scommesse live. Questa è una delle componenti più importanti in questo genere di siti, proprio perché punta su un’offerta diversa. Le scommesse live permettono infatti di giocare e puntare quando un match è ancora in corso di svolgimento.

Tale possibilità permette di sperimentare con strategie inedite, che mutano mentre cambiano anche le situazioni in-game. Questo può quindi tradursi nello sfruttamento di cambi repentini di quota, oppure in una rimonta completamente inattesa.

Le scommesse live sui siti scommesse non AAMS possono stravolgere completamente un’esperienza, specie quando sfruttate a dovere.

I bonus nei siti non AAMS per le scommesse

Uno dei punti più importanti nell’esperienza degli utenti con i migliori bookmakers non AAMS è quello dei bonus. I bonus sono infatti dei piccoli incentivi che mirano a incrementare il bankroll di gioco, oppure a offrire delle migliorie di scommessa. In ogni caso, sono un elemento che deve essere visionato attentamente, specialmente nei migliori siti scommesse non AAMS.

| Bonus | Descrizione generale |

| Bonus di benvenuto | Beneficio economico iniziale dedicato a tutti i giocatori che si iscrivono per la prima volta. |

| Bonus sulle scommesse multiple | Beneficio che viene riconosciuto sulle scommesse multiple, con più di due eventi. Punta ad incrementare le vincite. |

| Bonus freebet | Piccole scommesse gratuite concesse su determinati eventi di gioco scelti dalla piattaforma. |

| Bonus senza deposito | Beneficio economico erogato come un credito gratuito, spendibile sulle opzioni scelte dal sito. |

| Quote maggiorate | Quote con valore maggiore che permettono di ottenere vincite potenziate in caso di vittoria. |

Bonus di benvenuto nei migliori bookmaker non AAMS

I bonus di benvenuto nei bookmaker non AAMS sicuri sono la promozione più comune e sempre disponibile. Si tratta di una promo che viene calcolata sul primo deposito, che gli utenti fanno in sede della loro prima iscrizione. Grazie a questo bonus, gli utenti stessi ottengono un bankroll maggiorato all’inizio dell’avventura.

Bonus sulle scommesse multiple

I siti di scommesse non AAMS spesso includono anche dei bonus sulle scommesse multiple. Premiano chi combina più eventi nella stessa schedina, incrementando percentuali sulle vincite totali. Si tratta quindi di piccoli stimoli che possono spingere i giocatori più incerti a tentare la sorta con delle combinazioni particolari. I bonus multipla valgono solo quando la selezione è interamente vincente, tranne che su diversa segnalazione.

Bonus Freebet

I bonus noti come freebet sono una delle opportunità più interessanti dei bookmakers senza licenza. Questi benefici sono delle vere e proprie scommesse gratuite, offerte per fidelizzare gli utenti o incentivarli a puntare su nuovi eventi. Funzionano un po’ come i free spins sulle slot dei casinò.

Bonus senza deposito

Tra i benefici più noti nei bookmakers senza AAMS c’è ovviamente il bonus senza deposito. Questo beneficio non ha bisogno di una ricarica o di un versamento. Si tratta di un credito gratuito erogato a giocatori eleggibili scelti dalla piattaforma. Spesso, questo tipo di bonus si sostituisce interamente al bonus di benvenuto.

Quote maggiorate

Infine, nei bookmaker non AAMS sono quasi sempre presenti le quote maggiorate. Queste vanno a migliorare notevolmente il rendimento di specifiche quote, potenziando le eventuali vincite derivanti. Le quote di questo genere sono molto presenti, spesso su eventi di calcio o basket. Quando disponibili, se sfruttate a dovere, possono regalare emozioni forti.

I metodi di pagamento dei migliori bookmaker non AAMS

| Metodo | Sicurezza stimata | Commissioni |

| Carte di credito e Postepay | Media: possono esporre diverse tipologie di dati essendo direttamente associati ad istituti bancari. | Presenti, dipendenti esclusivamente dall’istituto che eroga il servizio. |

| PayPal e altri Wallet | Sicurezza di alto livello, grazie alla protezione acquisti ed alla gestione separata. | Le commissioni sono molto basse, legate al servizio. Non superano il 3% sulla spesa. |

| Bonifico bancario | Media: anche in questo caso è presente il rischio di esposizione dei dati personali e bancari dell’utente. | Commissioni sempre presenti e variabili a seconda della banca a cui ci si associa per il servizio. |

| Criptovalute | Altissima: essendo decentralizzate permettono di eseguire transazioni anonime ma tracciabili. | Commissioni ridotte al minimo grazie alla rete selezionata. |

Carte di credito e Postepay

Le carte di credito o di debito, così come la Postepay, sono un metodo frequente nei bookmaker non AAMS. Possono essere facilmente utilizzate per versamenti e prelievi, ma possono richiedere fino a 4 giorni per ultimare una transazione. Possono inoltre essere clonate, o le informazioni rubate da malintenzionati.

PayPal e altri Wallet

I wallet elettronici, come ad esempio PayPal, sono un metodo veloce e abbastanza sicuro per le transazioni economiche. Sono quasi sempre accettati dai bookmakers non AAMS, inserendo diverse modalità di acquisto. Le transazioni sono veloci (entro le 24 ore) mentre la protezione integrata consente di rimanere abbastanza al sicuro.

Bonifico bancario

I bookmaker non AAMS sono quasi sempre disponibili ad accettare anche i bonifici bancari. In questo caso, però, parliamo di un metodo di pagamento piuttosto obsoleto, superato sia dai wallet che dalle criptovalute. Richiede comunque diverso tempo, anche fino a 7 giorni, per una transazione completa.

Criptovalute

Infine, i bookmaker stranieri possono accettare anche le criptovalute. Queste sono delle monete digitali decentralizzate, che consentono quindi di slegarsi completamente dalle banche. In questo modo si raggiungono tempi di elaborazione ridottissimi (minuti o secondi), con un livello di sicurezza davvero importante. Rimangono dunque anonime ma tracciate, con costi e commissioni contenuti che ne agevolano l’utilizzo.

Pro e contro dei bookmaker non AAMS sicuri

Per chiudere la nostra visione completa dei bookmakers non AAMS, è giunto il momento di vedere insieme vantaggi e svantaggi. Anche se i punti positivi dell’offerta sono tanti, ciò non esclude l’esistenza di piccoli svantaggi. Per avere un quadro chiaro dell’intero mondo dei casinò online di questo tipo, è fondamentale conoscere entrambe le facce.

| Pro | Contro |

| Le quote sono spesso più alte, con mercati di ogni tipo e più vari. | Alcune condizioni di rollover o i requisiti di puntata possono essere un po’ articolati. |

| I bonus di benvenuto, le freebet e le quote maggiorate sono spesso erogate a somme più generose rispetto a quanto accade in Italia. | I metodi di pagamento diversi dalle criptovalute possono richiedere dei passaggi aggiuntivi per la verifica finale. |

| Grazie alle criptovalute, le transazioni economiche sono nettamente più veloci nella chiusura. | Alcune piattaforme meno frequentate possono presentare qualche piccolo bug o problema tecnico. |

| Le offerte di gioco e di catalogo, in generale, puntano alla modernità, integrando anche novità dell’ultimo momento. | Le interfacce di alcuni siti possono non essere tradotte interamente o correttamente in Italiano. |

Conclusione

In sostanza, i bookmaker non AAMS si posizionano sul mercato come la soluzione più moderna in assoluto per le scommesse sportive. Grazie alla licenza straniera diversa da quella italiana, possono infatti approcciare delle dinamiche di gioco innovative, svincolate dai controlli ADM. Questo porta quindi ad un numero maggiore di giochi online, bonus e promozioni più generosi, nonché metodi di pagamento decentralizzati come le criptovalute.

Al di là dei loro vantaggi, però, ricordate sempre che giocare sui bookmakers non AAMS significa anche usare bene la testa. La responsabilità del giocatore è fondamentale affinché egli stesso non cada vittima di errori pericolosi.